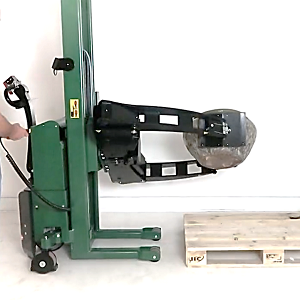

The Logitrans Rotator is used in many Food Production sites for safer handling of goods for operators. Rotators can be used for Pallets, Boxes, Crates and Dolavs. The Rotator has small dimensions (perfect for confined spaces) and a capacity of 1000 kg.

A stainless steel stacker with straddle legs is used in a pharmaceutical application for lifting and moving IBCs. Stainless steel pallet stackers are available with manual or electric lift. An explosion-proof version is also available for explosive environments classed as ATEX zones 1 & 2.

A Logitrans powered coffin handler is fitted with powered rollers and has 360 degree rotation, for precise and gentle movement of coffins and caskets. The coffin handler lifts, turns and transports coffins up to a maximum weight of 300kg (47 stones). This handler has fully powered lift, lower, slide and propulsion: preventing worker back and strain injuries at mortuaries, crematoriums and funeral directors.

A Logitrans Panther hand pallet truck has the customer name and logo cut into the truck's fork frame. Equipment losses can be a particular problem in transport and other applications, where pallet trucks move around frequently. Personalising trucks with a company name and logo can help to reduce loss and theft of expensive pallet truck equipment.

A Logitrans LFS Mini straddle pallet stacker fitted with a platform table, is used to lift Chep style pallets to a correct working height. The LFS Mini assists operatives packing pallets in a food production environment, and prevents back and shoulder injuries associated with repeat bending and stretching. This particular packing area was confined with limited room for pallet lifters. Pallets were closed (with bottom runners) and therefore a straddle lifter was needed to lift them - although a straddle stacker was initially ruled out, as they were thought too big for the work area. Logitrans were able to modify their LFS Mini so it was just wide enough for the pallet. This allowed the Mini to fit within confines of the customer's packing line. A stainless steel version is also available for food production high care areas.

A Logitrans Reel Rotator is modified for use in a large garden centre, to lift and turn heavy ceramic pots. The Rotator is used to lift the pots from pallets and transport them to the display area. The Handler has 180 degree rotation each way, enabling the pots to be tilted and turned, when filling and emptying them.

A Logitrans Rotator is used to lift heavy stillages and tip the components into a hopper. This particular model has fully powered lift, rotate and drive. Stillages can be transported to and from the hopper, with no effort on the part of the operator.

A Panther Silent hand pallet truck is used at an open air market, to move heavy items to and from a display stand. The Panther Silent has specially designed low friction wheels and can be used on uneven, gravel and stony surfaces. Unlike a standard pallet truck (which is difficult to pull and can ground out and get stuck), the Panther Silent can be moved on rough ground with relative ease.

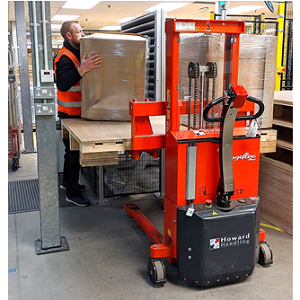

Logitrans SELF Maxi electric stacker trucks are used by a kitchen manufacturer. The stacker has an extra wide fork span to lift large pallets to a correct working height for packing. The stacker has powered drive, so pallets are transported to and from the warehouse with the same machine.

With over 50 years' experience, Danish manufacturer Logitrans produce exceptional quality hand pallet trucks, electric pallet trucks, pallet lifters & stacker trucks. They manufacture a unique range of box and crate turners & tilters, and reel & drum turners. Their range of stainless steel lifters includes scissor lifts & straddle pallet stackers, designed for food & pharma environments. Requests for special sized and custom bespoke lifters and handlers are welcomed. Used equipment is available.

The Logitrans range includes pallet trucks, scissor lift pallet trucks, electric stacker trucks & stainless steel pallet stackers, reel and drum turners The Logitrans product range and design focuses on the safety and ergonomic working conditions of the user. Logitrans ensures high quality through an extended test programme in co-operation with experts in Health and Safety.